Mastering Heat Transfer Vinyl: Choosing the Right Settings and Peeling Techniques

Heat Transfer Vinyl (HTV) has become a popular choice for customizing apparel, cork boards, accessories, and more. Whether you're a seasoned crafter or just starting, understanding the right settings and peeling techniques is crucial for achieving professional-looking results. In this blog post, we'll guide you through the optimal settings for Heat Transfer Vinyl and help you decide when to choose cold, warm, or hot peeling.

Setting the Stage: Optimal Heat Transfer Vinyl Settings

1. Temperature: Different types of HTV require specific temperature settings. Always refer to the manufacturer's instructions for the recommended temperature range. - Typically, temperatures range from 275°F to 374°F (135°C to 190°C). Lower temperatures are suitable for delicate fabrics, while higher temperatures are ideal for thicker materials.

2. Pressure: Adjust the pressure on your heat press machine according to the thickness and type of material you're working with. Insufficient pressure may result in incomplete adhesion, while excessive pressure can damage the vinyl or substrate. If you're using an iron instead of a heat press adjust by how much force you push down with.

3. Time: The recommended pressing time can vary based on the HTV brand and material. A typical range is 10 to 15 seconds, but some vinyl may require longer durations. Always consult the product guidelines for accurate timing.

4. Peel Type: The type of peel (cold, warm, or hot) is a crucial factor in achieving the best results. Let's delve into when to choose each method.

To see all of our Machine Settings and Cheat Sheets click here.

Peeling Techniques: Cold, Warm, and Hot

1. Cold Peel:

- When to Choose: Cold peeling is suitable for heat transfer vinyl that has a thicker carrier or backing. Wait for the material to cool completely before peeling off the carrier sheet. -

- Benefits: Cold peeling reduces the risk of accidental stretching or distortion of the design. It's ideal for intricate designs or small details.

2. Warm Peel:

- When to Choose: A warm peel is suitable for most standard HTV materials. Peel the carrier sheet off when the design is still warm to the touch.

- Benefits: Warm peeling strikes a balance between the precision of cold peeling and the ease of hot peeling. It's a versatile option for various projects.

3. Hot Peel:

- When to Choose: Hot peeling is recommended for materials with a thin carrier or when you need a quick turnaround. Peel the carrier sheet immediately after pressing.

- Benefits: Hot peeling is convenient for mass production or projects with tight deadlines. It provides a smooth, glossy finish and is often preferred for larger designs.

Conclusion:

Mastering Heat Transfer Vinyl involves finding the right balance of temperature, pressure, and peeling technique. By understanding the characteristics of your HTV and following the manufacturer's guidelines, you'll be well on your way to creating professional-looking customized crafts. Whether you choose cold, warm, or hot peeling, each technique has its own advantages, allowing you to tailor your approach based on the specific needs of your project. Happy crafting!

Recent Posts

-

NEW Holographic Eclipse Heat Transfer Vinyl

April 15th, 2024 3 Ways to Use the New Holographic Eclipse Heat Transfer Vinyl from Siser …Apr 29th 2024 -

Hop into Spring with Cute Easter Vinyl Crafts

Do you love our Vinyl? Sign up for Vinyl Club today to get FREE vinyl and save big! …Mar 28th 2024 -

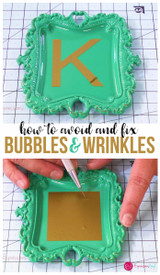

Fixing Wrinkles and Bubbles in Vinyl

How do you get air bubbles out of vinyl? There are a few different ways to ensure a flawless …Mar 26th 2024