What is Dwell Time?

I was in the kitchen trying to peel off an old sticker from my favorite coffee mug when it struck me – the stubborn sticker was a perfect metaphor for craft vinyl adhesion. Just like that sticker, the secret to a flawless vinyl project lies in understanding a little thing called dwell time.

Let’s dive into what makes dwell time so crucial for those pressure-sensitive adhesives (PSAs) we all rely on in adhesive vinyl. It’s all about the bond – the strength of the peel adhesion force of PSAs really depends on the dwell time. Picture this: after pressing your vinyl onto a surface, it keeps adapting, molding itself more firmly over time. And it’s not just about the time; the adhesive’s own characteristics play a role too. Some are tough cookies, barely changing their grip with time, while others might need a bit more patience to reach their full potential.

Now, if you’re working in a warm space, think of it as a fast-forward button for dwell time. The warm environment mimics a longer dwell time, thanks to our friend, the Time-Temperature Superposition principle. This basically means that what happens at higher temperatures can also happen over a longer period at room temperature.

In the real world, we often stick our vinyl and leave it be for a while before any action – like peeling or repositioning – takes place. This is why it’s important to know how your vinyl behaves both after a quick stick (think minutes) and a long lounge (days, even a week).

Surface prep is your best friend here. A clean, welcoming surface means a stronger bond. Any dirt or oil is like an unwanted guest at a party – it just gets in the way. A good cleaning can make all the difference.

Speaking of making a difference, how you apply your vinyl matters too. A nice, firm press and some dwell time are essential for that bond to really set. Most adhesives like it best at cozy room temperatures, but keep in mind, each one may have its own preferred climate.

Texture time! Rough surfaces are like high-maintenance friends; they need more time and attention. Depending on how textured your surface is, you might need to give it up to 72 hours of dwell time before you can trust that bond to hold strong.

And don’t forget, even pressure is key. Think of it like a good massage – consistent and even to get that adhesive flowing just right and pushing out any pesky air bubbles.

In short, dwell time isn’t just a waiting game – it’s the secret ingredient to ensuring your vinyl projects stick around just as long as you want them to. It’s all about understanding and respecting the process to get that perfect, lasting bond. Let’s give our projects the time they deserve to really shine.

Recent Posts

-

NEW Holographic Eclipse Heat Transfer Vinyl

April 15th, 2024 3 Ways to Use the New Holographic Eclipse Heat Transfer Vinyl from Siser …Apr 29th 2024 -

Hop into Spring with Cute Easter Vinyl Crafts

Do you love our Vinyl? Sign up for Vinyl Club today to get FREE vinyl and save big! …Mar 28th 2024 -

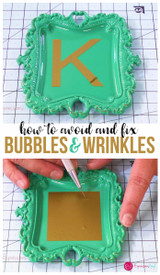

Fixing Wrinkles and Bubbles in Vinyl

How do you get air bubbles out of vinyl? There are a few different ways to ensure a flawless …Mar 26th 2024